With the world changing at an ever-faster pace, the only way to retain one’s leadership is to exchange new ideas. A hundred years ago, the Russian avant-garde was a source of a new way of thinking in the arts for the entire world.

avant-garde efficiency

Selecting the best quality refractories, which help increase the life of heat-containing industrial vessels lining, is an important factor in improving performance of a high-temperature production facility. We know how to achieve consistent results in this area and offer you new opportunities provided by a unique magnesite deposit in Siberia.

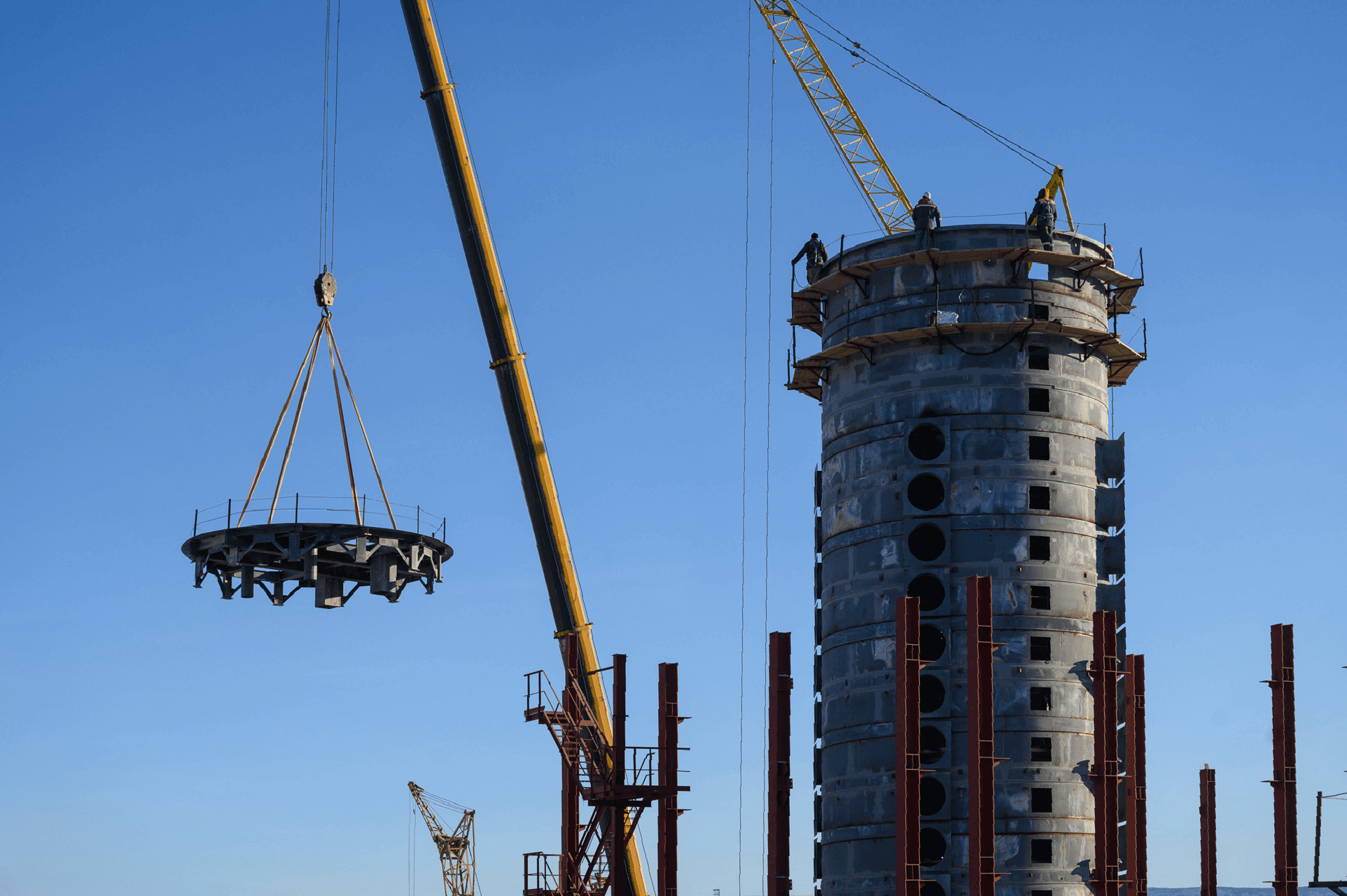

In 2011, Magnezit Group obtained a license to develop the Talsk magnesite deposit in Razdolinsk (Krasnoyarsk Territory), which is the largest high-quality magnesite deposit on the continent.

In 2011, Magnezit Group obtained a license to develop the Talsk magnesite deposit in Razdolinsk (Krasnoyarsk Territory), which is the largest high-quality magnesite deposit on the continent.

Together with the neighboring Kirgiteisk deposit, which the company has been developing since 2006, the Talsk magnesite deposit makes up the Group’s source of unique magnesite ore in Siberia, with 107.8 million metric tons in known reserves of crystalline magnesite.

Found in the heart of the Siberian taiga, our magnesite possesses unique qualitative characteristics. It is pure and has consistent chemical composition, with an MgO content of up to 98,5% on an ignited basis, and a minimum of impurities.

Since early 2013, magnesite ore has been produced in Razdolinsk on a commercial scale and has become part of the production cycle at the Nizhne-Priangarsk and Satka production sites, securing a source of unique, high-quality ore for the company for more than 100 years to come.

avant-garde quality

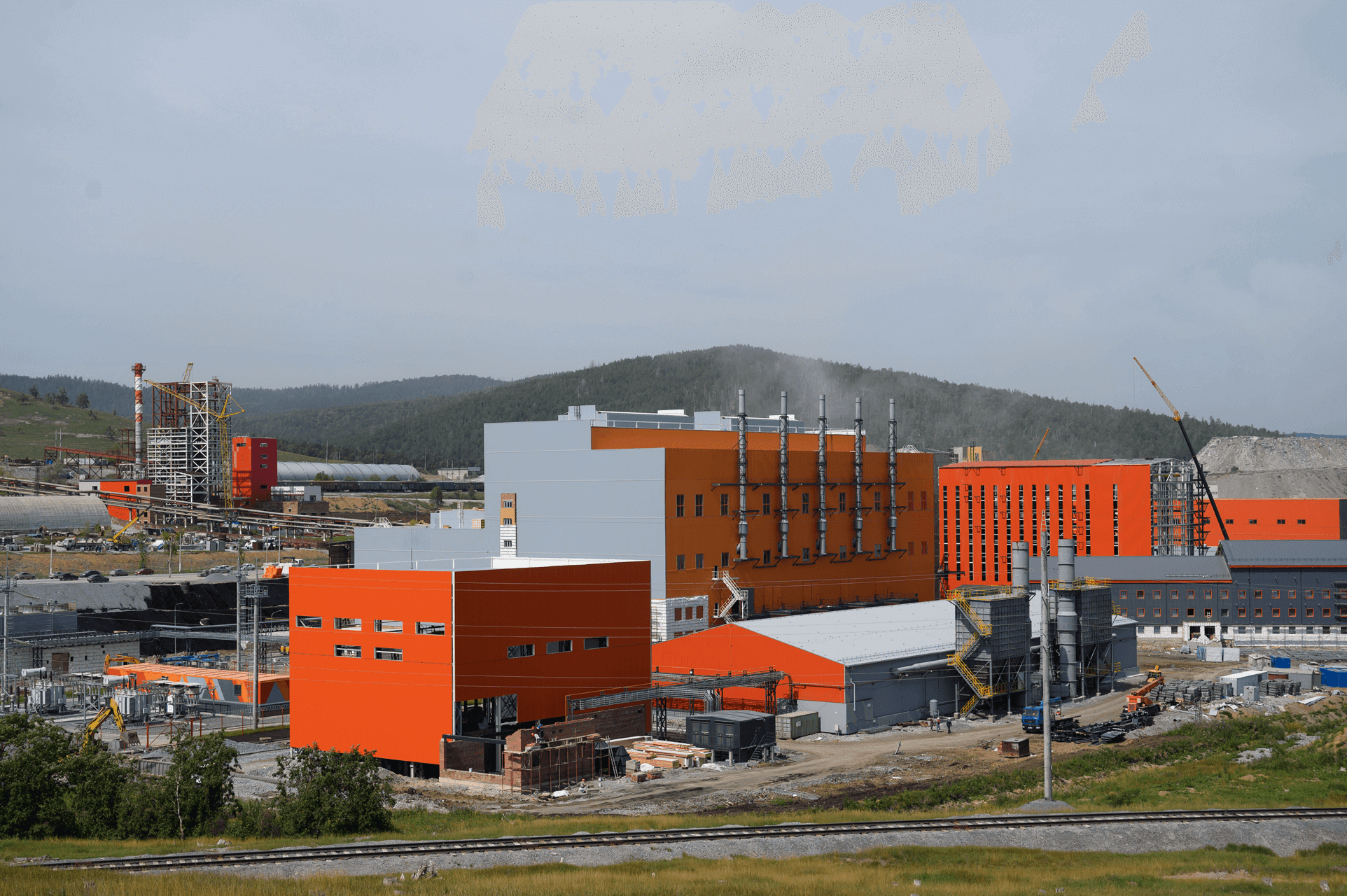

Today’s high-temperature production facilities need refractory solutions capable of withstanding ever-more-demanding process modes. The quality of such solutions depends on the magnesite ore they are based on, as well as on the processing technologies. We mine unique magnesite at our own large deposit in Siberia. To preserve all of the ore’s useful properties, we are establishing a leading-edge processing facility.

avant-garde quality

Today’s high-temperature production facilities need refractory solutions capable of withstanding ever-more-demanding process modes. The quality of such solutions depends on the magnesite ore they are based on, as well as on the processing technologies. We mine unique magnesite at our own large deposit in Siberia. To preserve all of the ore’s useful properties, we are establishing a leading-edge processing facility.

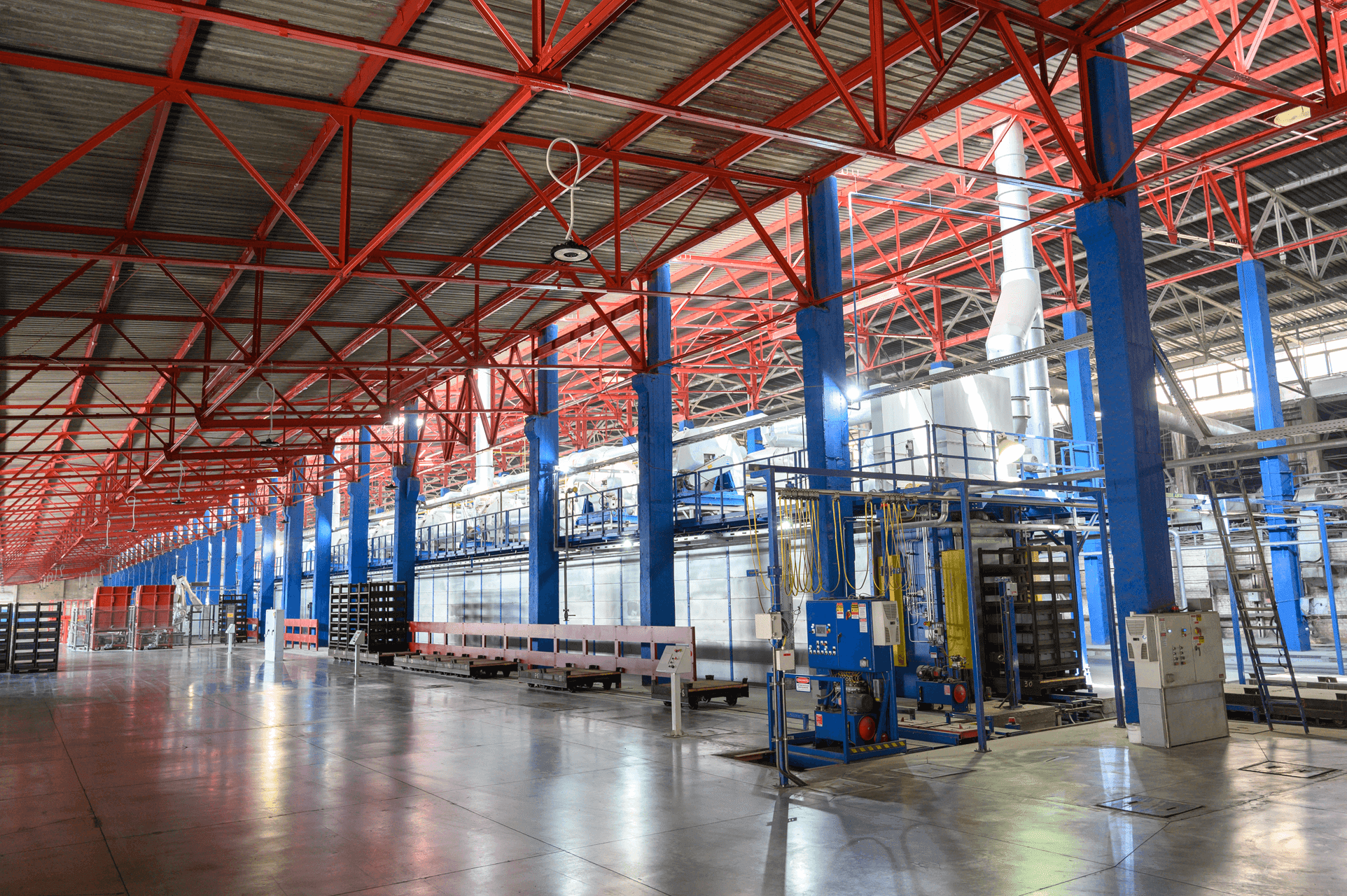

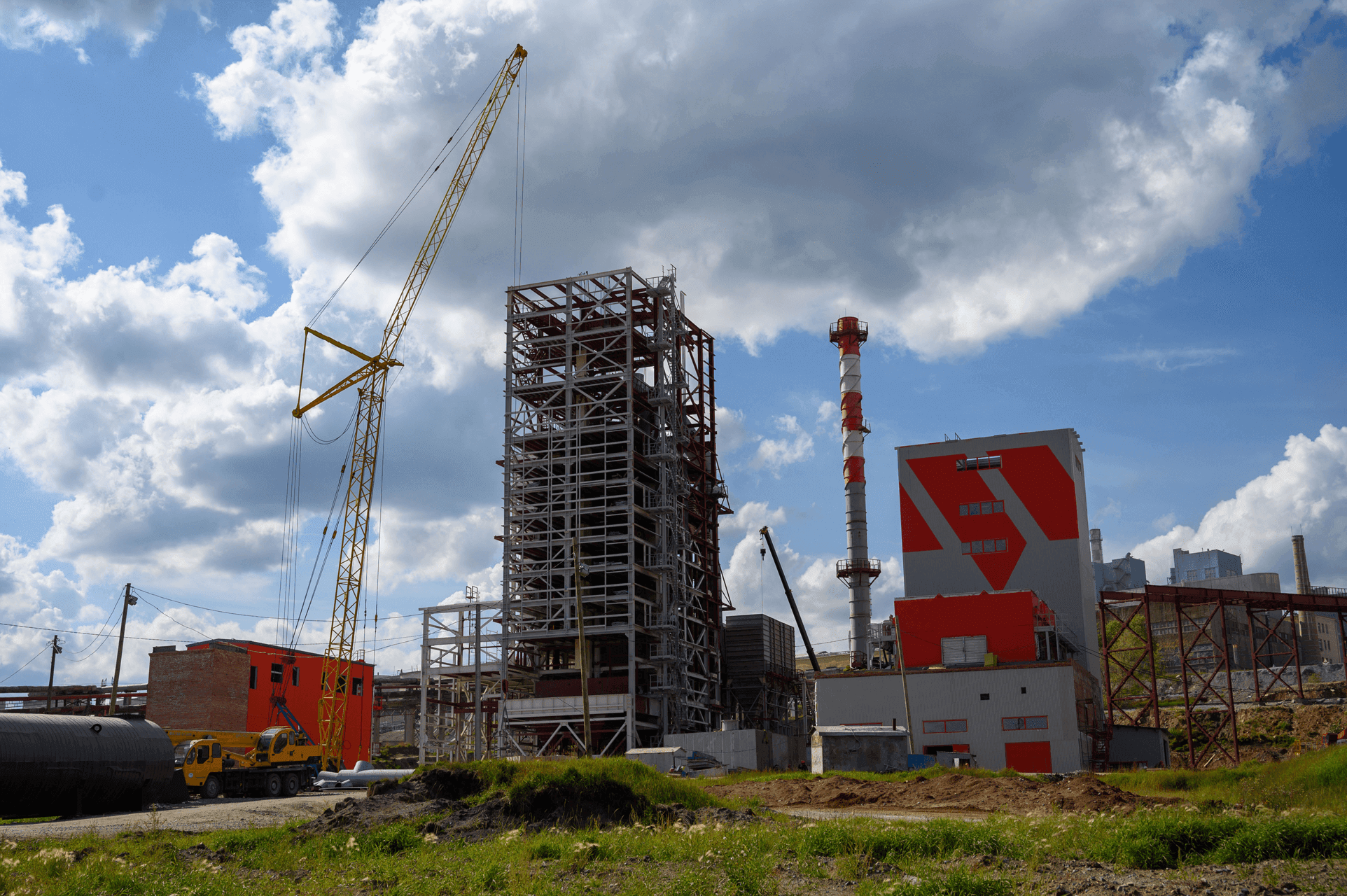

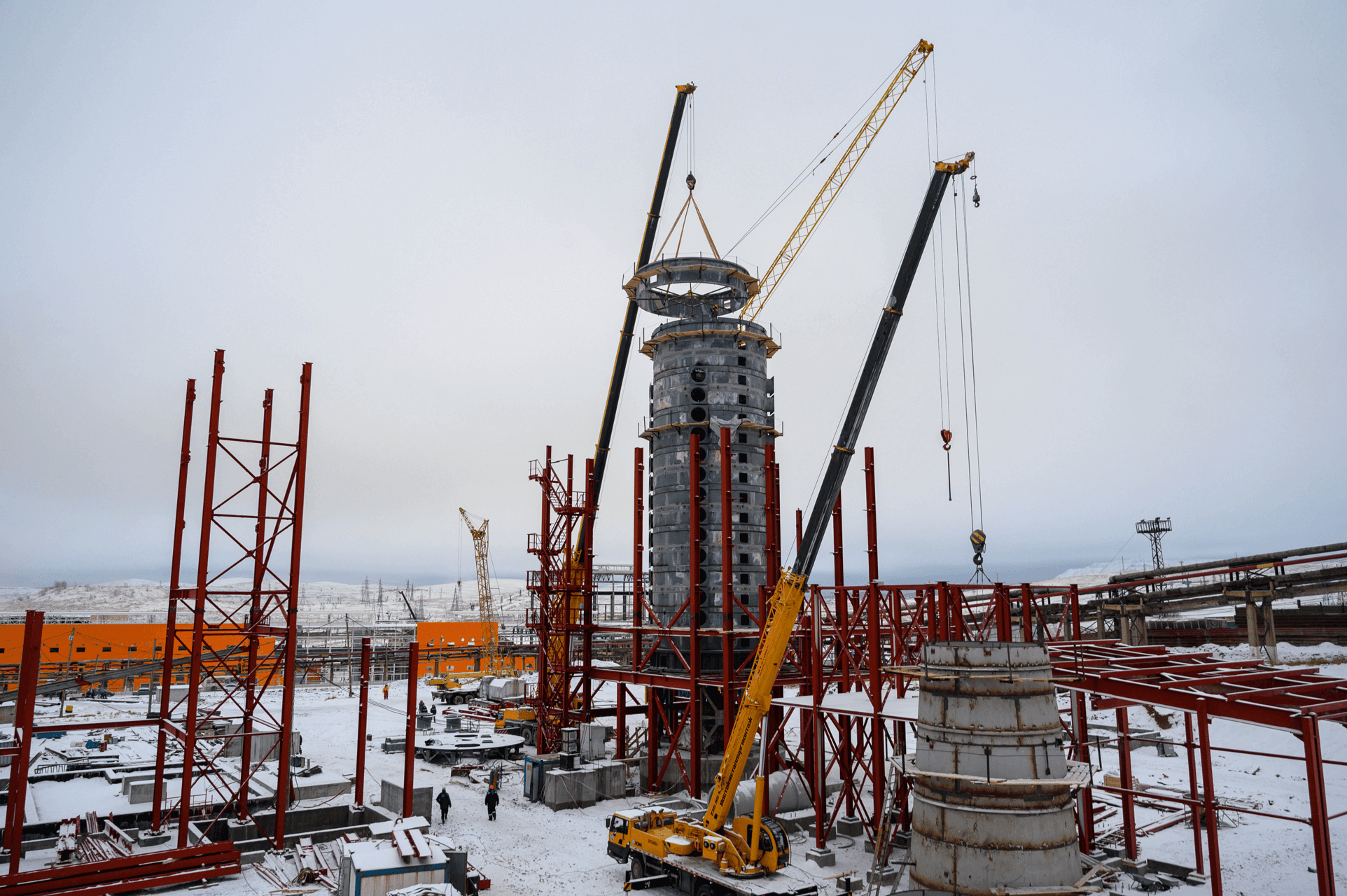

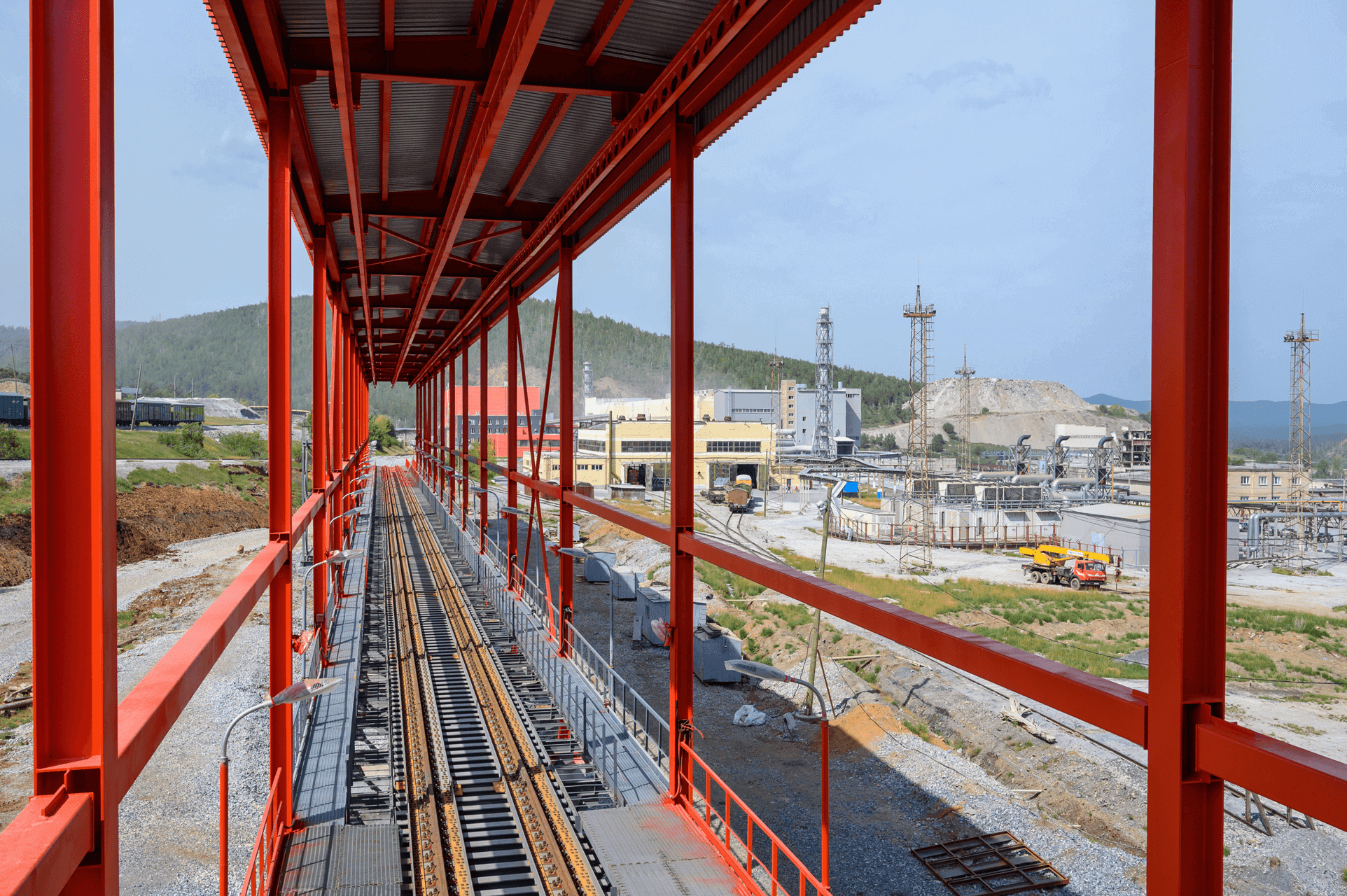

Since 2011, Magnezit Group has been extensively upgrading its two leading production sites — the Satka plant in Chelyabinsk Region and the Nizhne-Priangarsk plant in Krasnoyarsk Territory. The new, optimized system of production integrates advanced facilities extracting raw materials and manufacturing high-quality intermediate and end products into a single workflow.

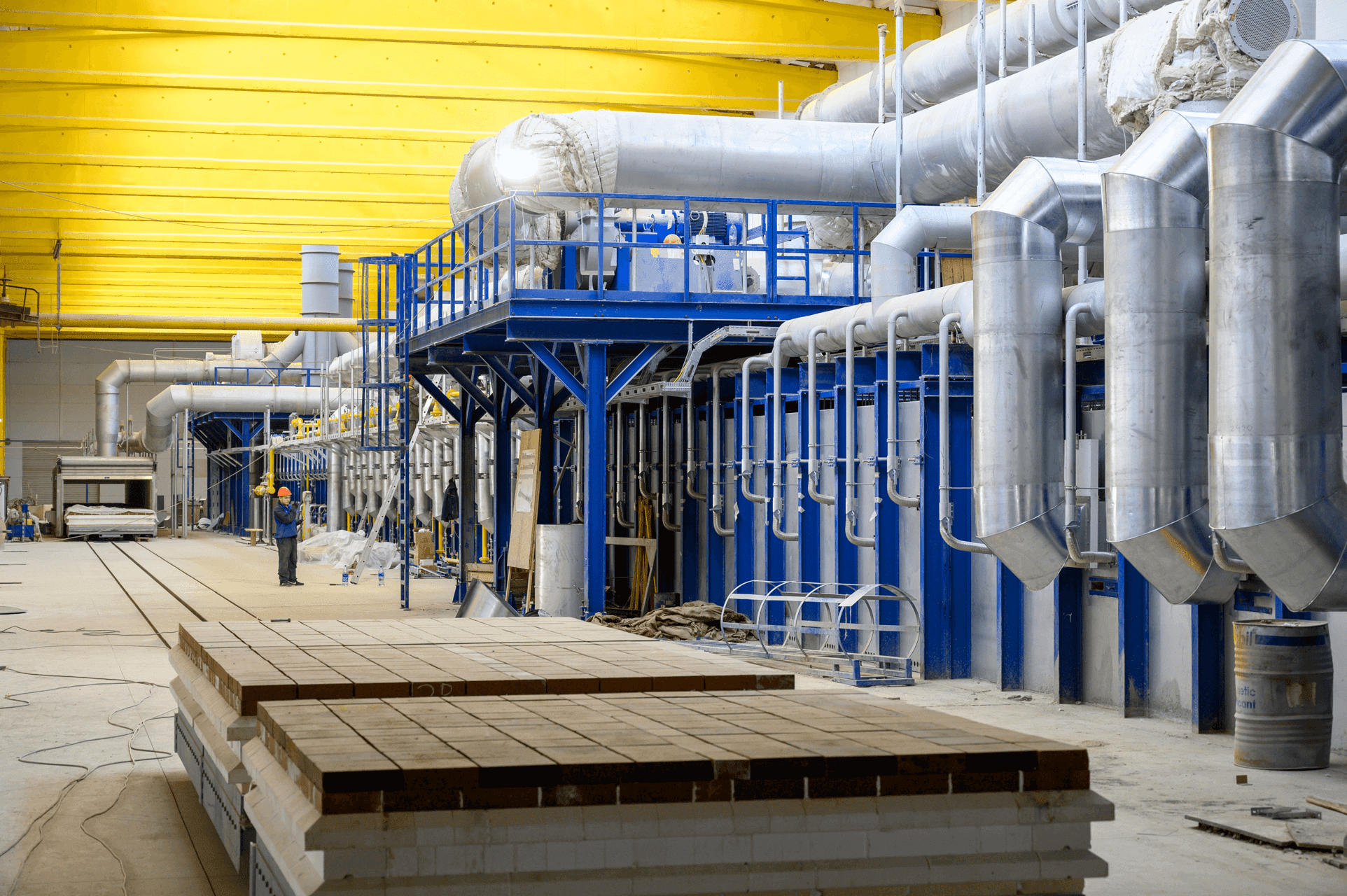

With our vast experience we are able to make the best use of proprietary engineering and technological know-how in combination with equipment from best-in-class global suppliers. We partner with SMS Group, Thyssenkrupp Industrial Solutions, Riedhammer, Allgaier Group, Laeis, Steinert, Schneider Electric, Wassmer Spezialmaschinen, Scheuch, Bepex International, Maschinenfabrik Gustav Eirich and other leading providers of industrial technology solutions. The most part of the equipment made by our partners has no rivals in the world and is tailored to the specific characteristics of our raw magnesite.

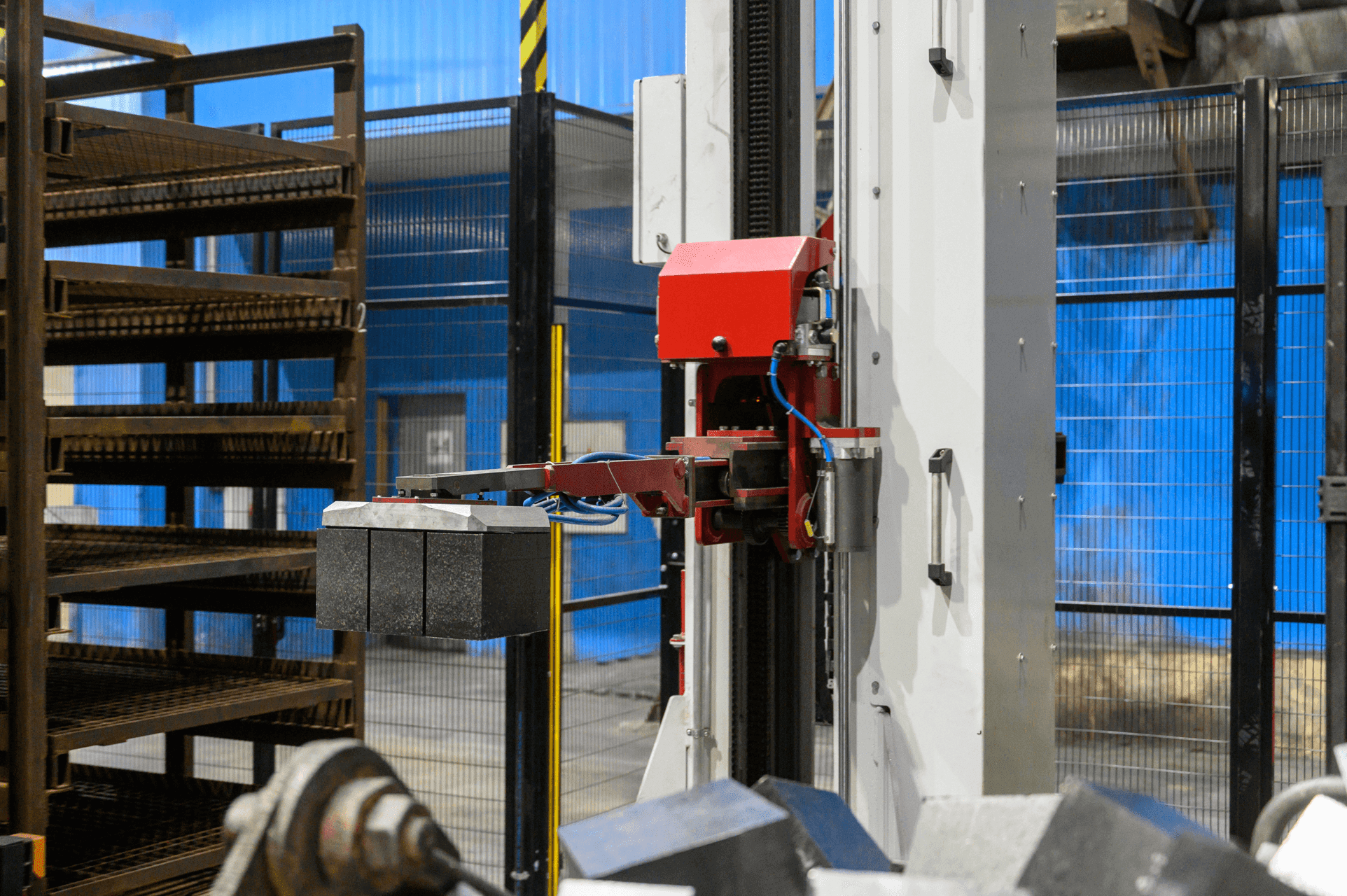

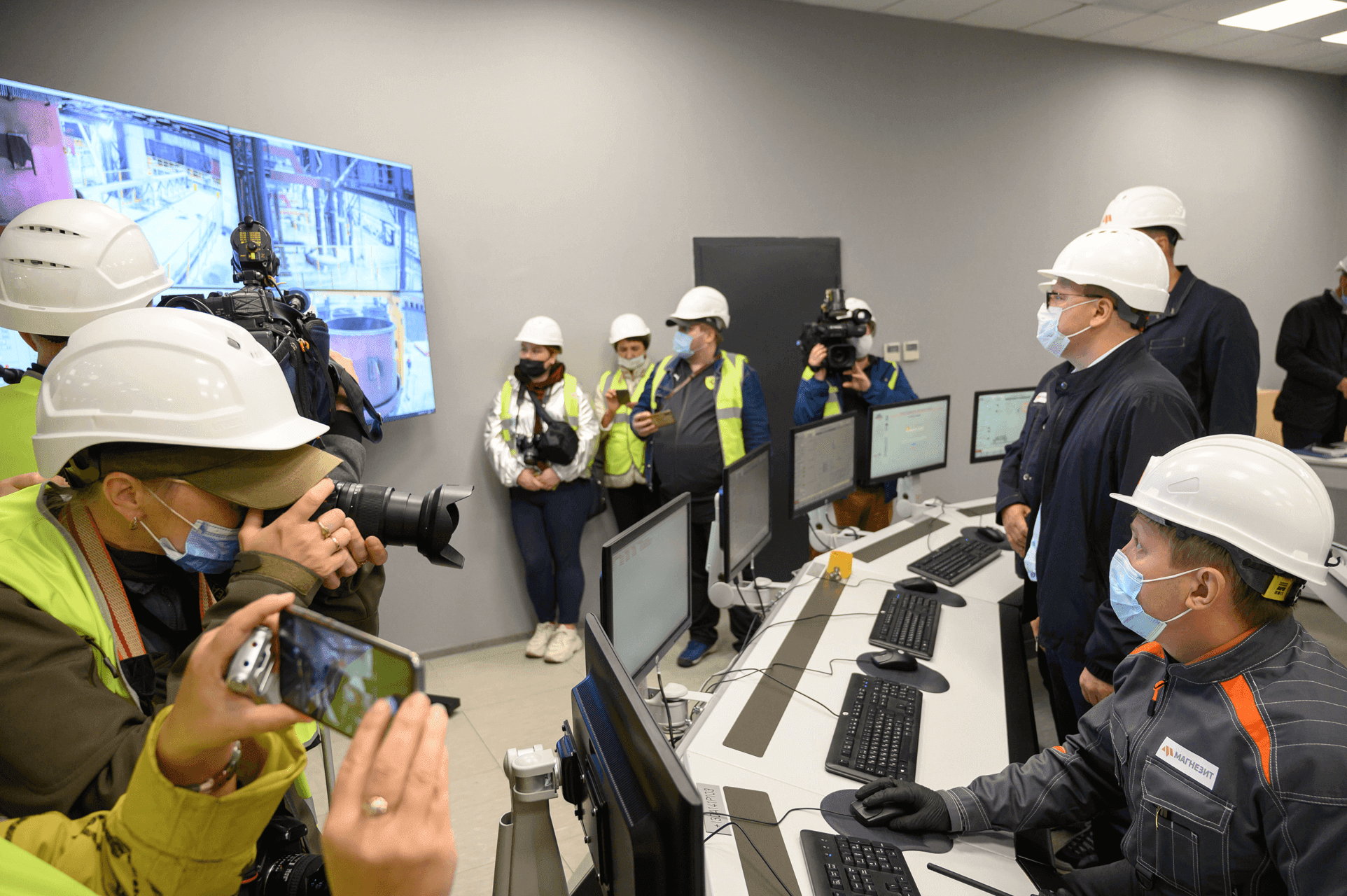

We deliver the highest level of robotic automation for production processes, designing them as software-controllable, flexible workflows to manage our product range based on customer needs. Our goal is to achieve technological leadership that will ensure the perfect quality of our products.

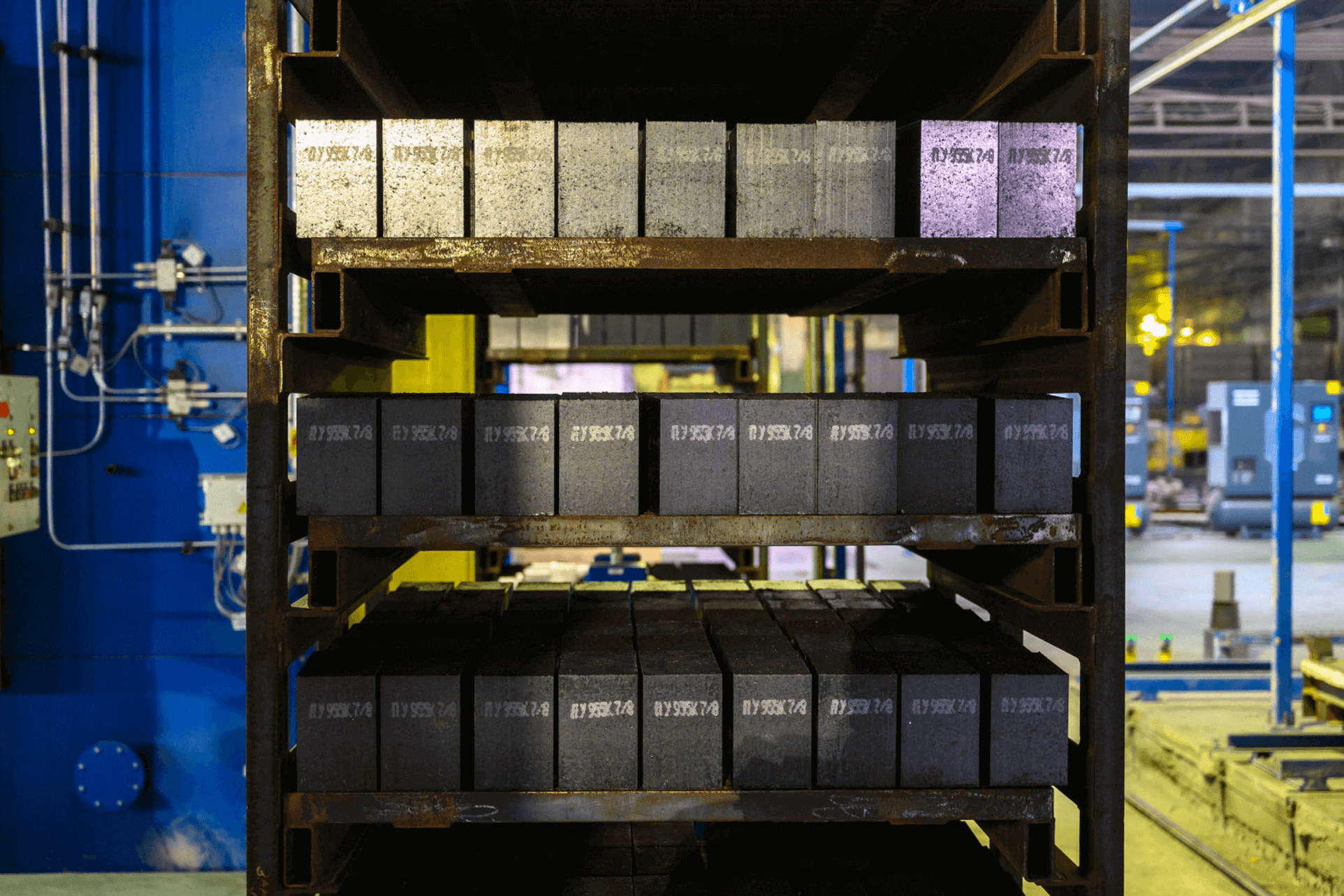

Today, we are the only Russian company that produces fused and dead-burned magnesia using a double-step technology — first, we decarbonize raw magnesite and briquet it, then it is dead-burned and fused. The cooling system provides controlled and gradual decrease of block temperature in the furnace bath. All combined, this ensures an even structure of high-purity coarse-crystalline magnesia. Refractories based on such a refined product are characterized by high density and resistance for harsh service conditions.

We have integrated an automated quality control system on our new production lines. It tracks every parameter of each production run across all stages — mixing, shaping, thermal treatment, and firing. The end-product sorting system we are putting into operation is the first of its kind in the global market. It analyzes each piece based on dozens of quality criteria, including possible internal damages analysis.

All modernization program initiatives are designed for sustainable use of raw materials and energy. We strive for minimization of the environmental impacts to ensure 100% ecological compliance.

Unique technological solutions in combination with equipment from best-in-class global suppliers

avant-garde opportunities

The unique Siberian magnesite deposits and state-of-the-art processing technology make it possible to improve the entire range of our products and manufacture new high-quality materials, which we have called Russian Magnezit. We use them to make refractories with the most advanced performance characteristics. The new level of product quality is supplemented with a well-developed global logistics, engineering and service network.

Russian Magnezit is a new flagship line of materials for manufacturing high-performance refractory products used in heat-containing vessels.

Russian Magnezit is a new flagship line of materials for manufacturing high performance refractory products used in heat-containing industrial vessels. Russian Magnezit is fused and dead-burned magnesia with an MgO content up to 98,5% and above. We produce it from the unique Siberian magnesite with a double-step technology.

Today, we use Russian Magnezit to make a wide range of refractories. The unique performance characteristics of the raw materials made it possible for us to greatly improve the quality of our refractory products.

RUSSIAN MAGNEZIT OFFERS A NEW LEVEL OF QUALITY FOR

-

Magnesia-carbon refractory products for lining critical areas of heat-containing vessels: converters, electric arc furnaces, and ladles for steel foundries

-

Magnesia-spinel products for lining rotary furnaces used for making cement clinker

-

Magnesia products with an MgO content of 95% and above used in air heaters of glass melting furnaces, as well as for lining ferroalloy furnaces and lime kilns, etc.

Contact our managers via info@magnezit.com to learn more about Russian Magnezit and our product range.

Use refractories based on Russian Magnezit to open new horizons for your business. Avant-garde your plans.

RUSSIAN MAGNEZIT OFFERS A NEW LEVEL OF QUALITY FOR

-

Magnesia-carbon refractory products for lining critical areas of heat-containing vessels: converters, electric arc furnaces, and ladles for steel foundries

-

Magnesia-spinel products for lining rotary furnaces used for making cement clinker

-

Magnesia products with an MgO content of 95% and above used in air heaters of glass melting furnaces, as well as for lining ferroalloy furnaces and lime kilns, etc.

Contact our managers via info@magnezit.com to learn more about Russian Magnezit and our product range.